OK, bit of a backstory here as I'm at my wits end trying to figure this out. Have had a handful of Prusas and then made the jump to Bambu a couple years back with a few A1's. Have done probably 12-15 SL15's on a .4 nozzle all out of a handful of PolyMaker PLA PRO across all 3 of them and never had a single issue on any of them.

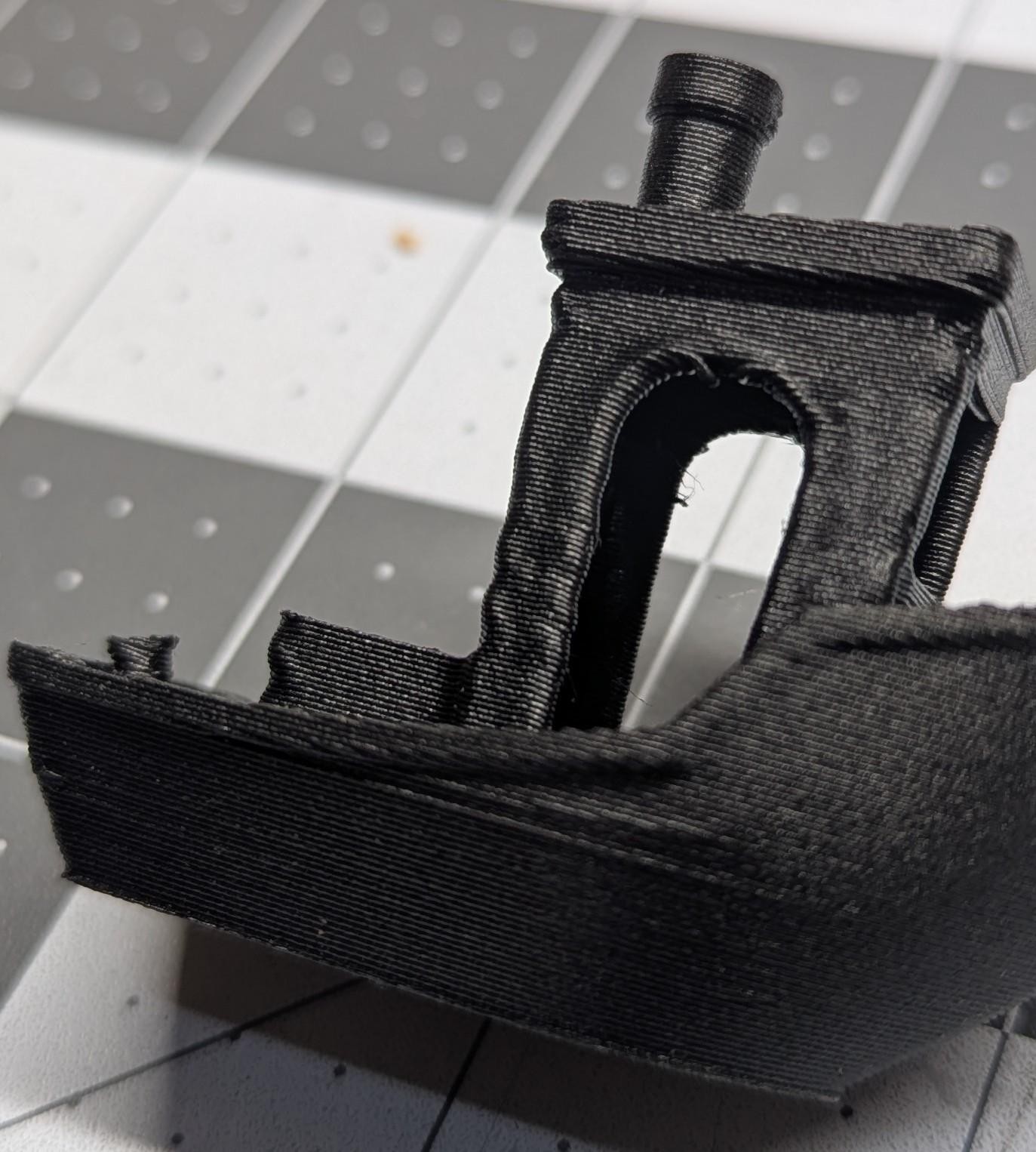

Been wanting to dive into some better plastics so I bought an X1C and some PolyMaker PET-CF and a .6 nozzle as I see suggested everywhere here when talking about PET-CF. I made probably 20 benchys and one aborted AL15 on the PM PET-CF and every single time I'm getting wavy corners on the "right angle" faces if that makes sense, see pics. It doesn't effect the other parts of the prints, just right angles. I figured I would dial in my profile before switching to the more expensive Bambu PET-CF but I just couldn't ever get past the wavy corners.

I did a manual pressure advance test or whatever it's called, tried using auto settings, tried letting the lidar figure it out, dried the roll to under 20% relative humidity, tried a second roll, even bough a second .6 nozzle and still getting the issue. Found a few examples showing the same corners online but none of those threads ever had solutions either. Tried a few different temps, no change there either, door opened or door closed

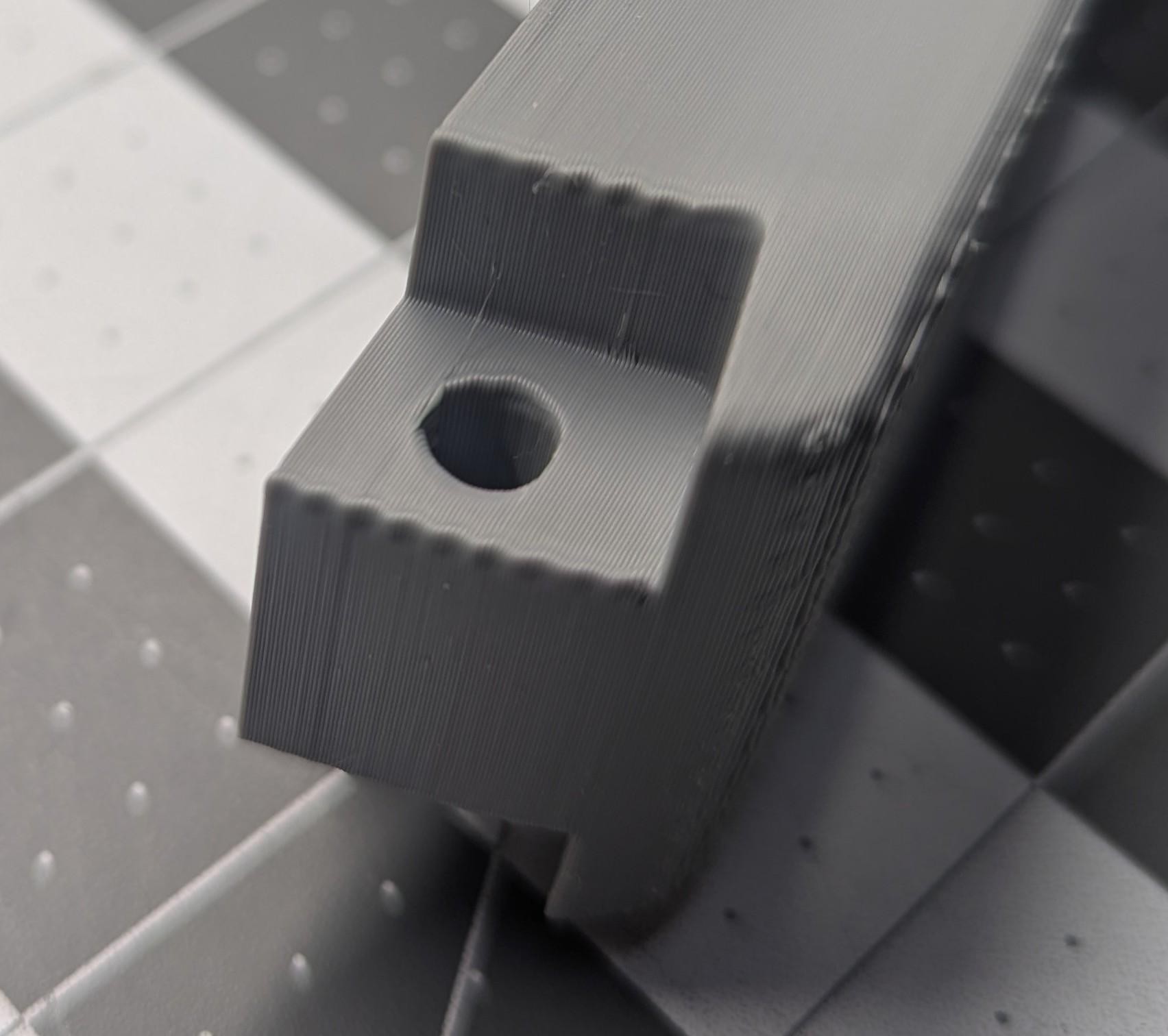

I went scorched earth and ended up selling that and getting a brand new H2S, seeing as I had success with A1's on .4 surely their flagship now with the A1 tool head would work? Printed a few dragons for the kid to just make sure the machine worked, they were flawless, and then I switched to a .6 nozzle and started the attempts to dial in again on this machine but now I'm getting the same wavy corners (see the grey pic, that a SL-308 attempt I canceled because it has the same thing going on) on this one too, and this is using a brand new and dried roll of PM PLA PRO.

I have no clue what else to try here, at this point because I'm 2 good quality printers in I'm assuming it's an issue with .6 in general? I could go back to .4 and try one there but the end goal is .6 for better filaments because from people here it sounds like they can get .6 working for them, I just sure as heck can't lol.

Any help would be great, I have no idea what else to try here

Also as a side note, I'm getting weird pock marks (tiny divots) on what I think at the seam spots on the .6 now, never really saw that before on the .4's. I haven't tried to address that yet as it's just now a thing on the H2S but I feel like finding a fix for that will be easier, my main focus is the dang corners not looking like potato chips but figured I would toss this in here incase someone had a simple quick fix I could toss into the testing rotations