I have a some experience with composites and have been toying with a process for printing parts a little differently than recommended in order to allow for some post print epoxy infusion treatments that would hypothetically produce a part that is stronger and more heat resistant.

Has anyone tried this and if so what was the outcome?

If not I am down to document my findings here as I proceed.

My progress so far is limited to:

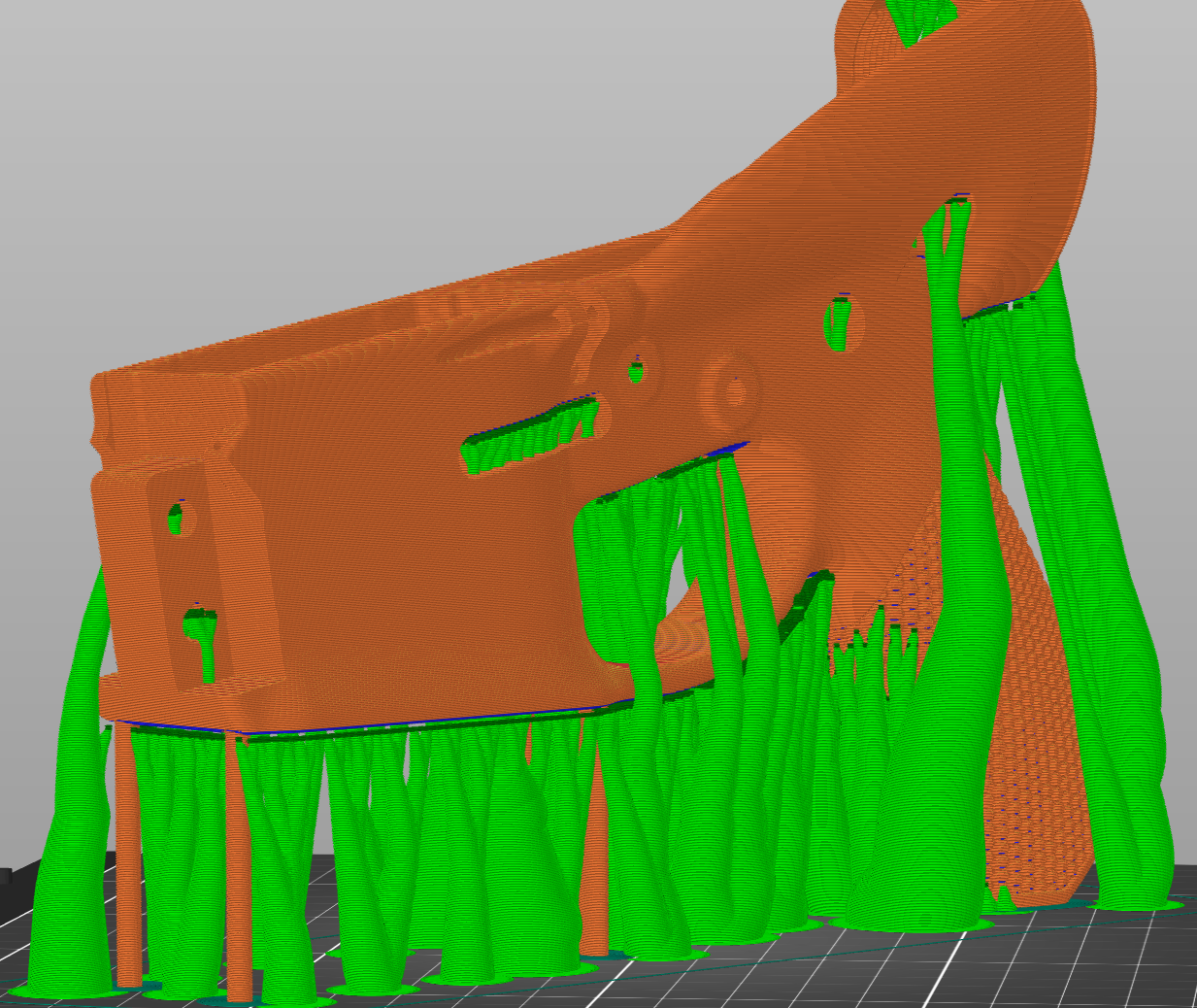

Modeling a port that I can import into the slicer and attach to the body of the part at strategic locations for post print epoxy infusion (using a vacuum pump to draw a two stage epoxy into the part.

Slicing the part to allow the epoxy to be infused (hoping no vacuum bagging required due to the part having perimeter walls), essentially making the interior of the part an open cell "foam" (85% gyroid infill) that allows the epoxy to infiltrate the entirety of the part (or at least all of the infill). Printing the part with minimal perimeters (more volume of the part is infused).

Potential benefits:

Increased tensile strength, improved stiffness (modulus), reduced creep (could reduce/eliminate issues with nylon), and reduced environment stress cracking (could reduce/eliminate issues with polycarbonate). It may even improve the performance of Gucci filaments like PPA, PPS, PEEK, PEKK, PEI...but I don't have a Gucci printer.

Potential infusion port locations in this slice

This could also be a way to introduce other reinforcements like glass bead or even kevlar and carbon fibers that could potentially amplify those benefits.