I gave up on ABS in 2012 for a few reasons. One is that it was very hard to make parts that were not warped, or if they would even stick to the bed. Another is that it smelled when printing. Also, I knew that PLA was stronger and PLA+ had as much impact resistance. Yes, ABS had temp resistance, which is often important, but I would just use PETG or PA for higher temp, depending on the application.

But, I got a Bambu H2D (mostly so that I could use dedicated support), and decided to try ABS again - as so many industrial printers focus on that. It printed so nicely. It had no smell. The prints "look" much nicer than PLA because they have a waxy matte/look rather than cheap/glossy. They are easy to sand, which is not the case with PLA. It stuck to the bed without any glue. I am stunned by the quality of this printer with ABS, and I presume, ABS-GF as well.

Maybe the heated chamber makes the layer bonding good enough so that it is worth revisiting ABS for people who have this printer? I am not set up to complete any frames due to work commitments, but would be very interested in the results of torture testing an Orca and Glock frame with ABS vs ABS-GF vs PET-CF vs PLA+

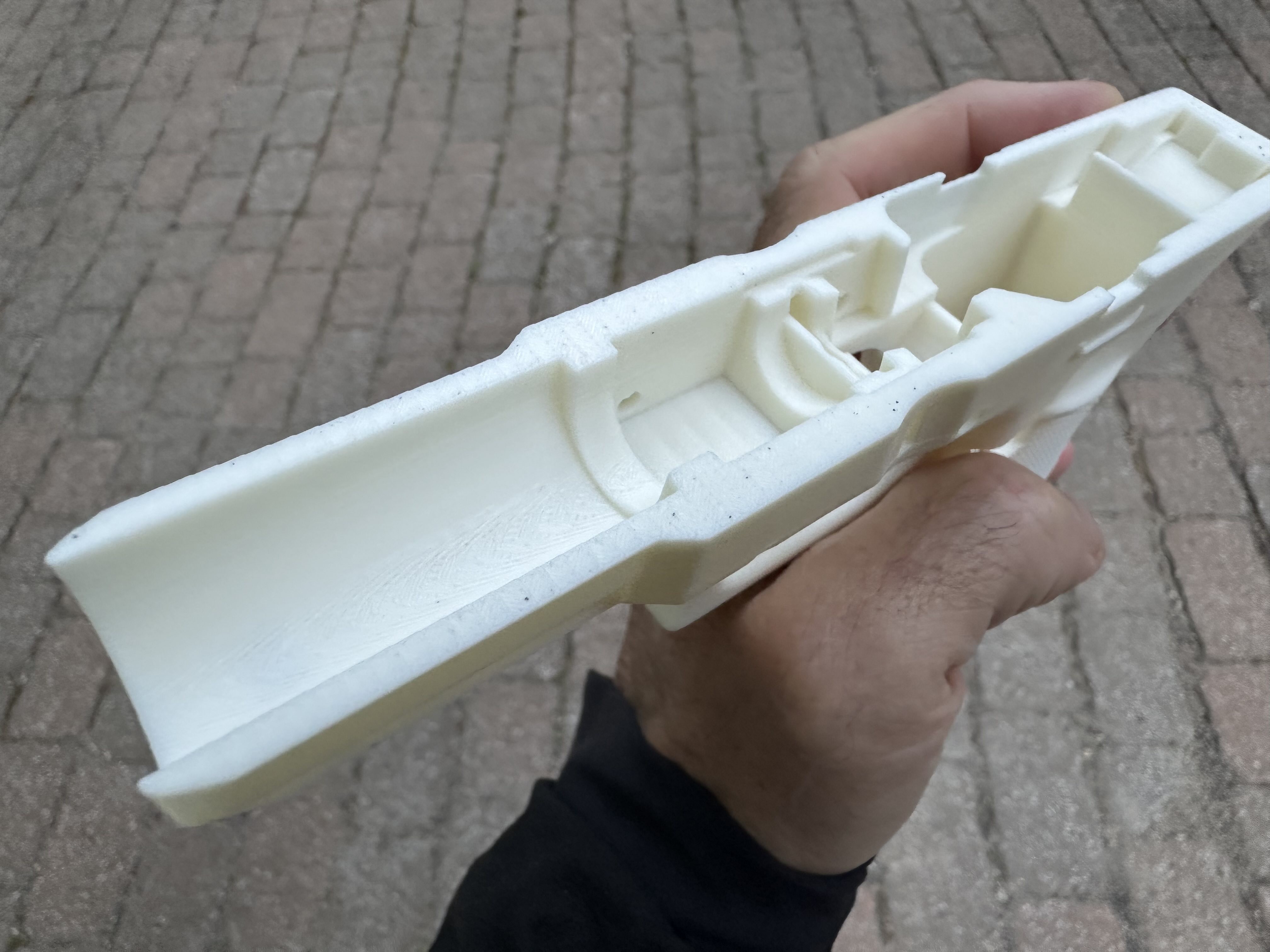

Here is what the quality looks like: