update. after many many tries and attempts. i think ive figured out what was going on. it was a mix of support issues and infill issues. my rats nest i was making was due to supports some how just collapsing and failing. there was no head strike on any parts. the supports would just fail. then having a bunch of nubbins hanging off the side. i think hoffman said it was due to over extrusion. i dialed my extrusion back. from 100% to the instructions recommended 95%, which still yielded over extrusion. i backed it off to about 85% for the main front of the receiver. i watched and it looked like polytough PETG has an expansion to it. because on my modified prints i still had over extrusion issues as well as the printed parts look like they had a full 100% infill. i will probably do an autopsy on some of the junk prints to check infill later.

i had to resort to using as tough of supports as i could to get the supports to not fail. which led me to beating the hell out of one printed part. but some fine tuning got that down to something a little less crazy to get off. the prints look much better. still a bit rough in places but they are acceptable for me now at this point.

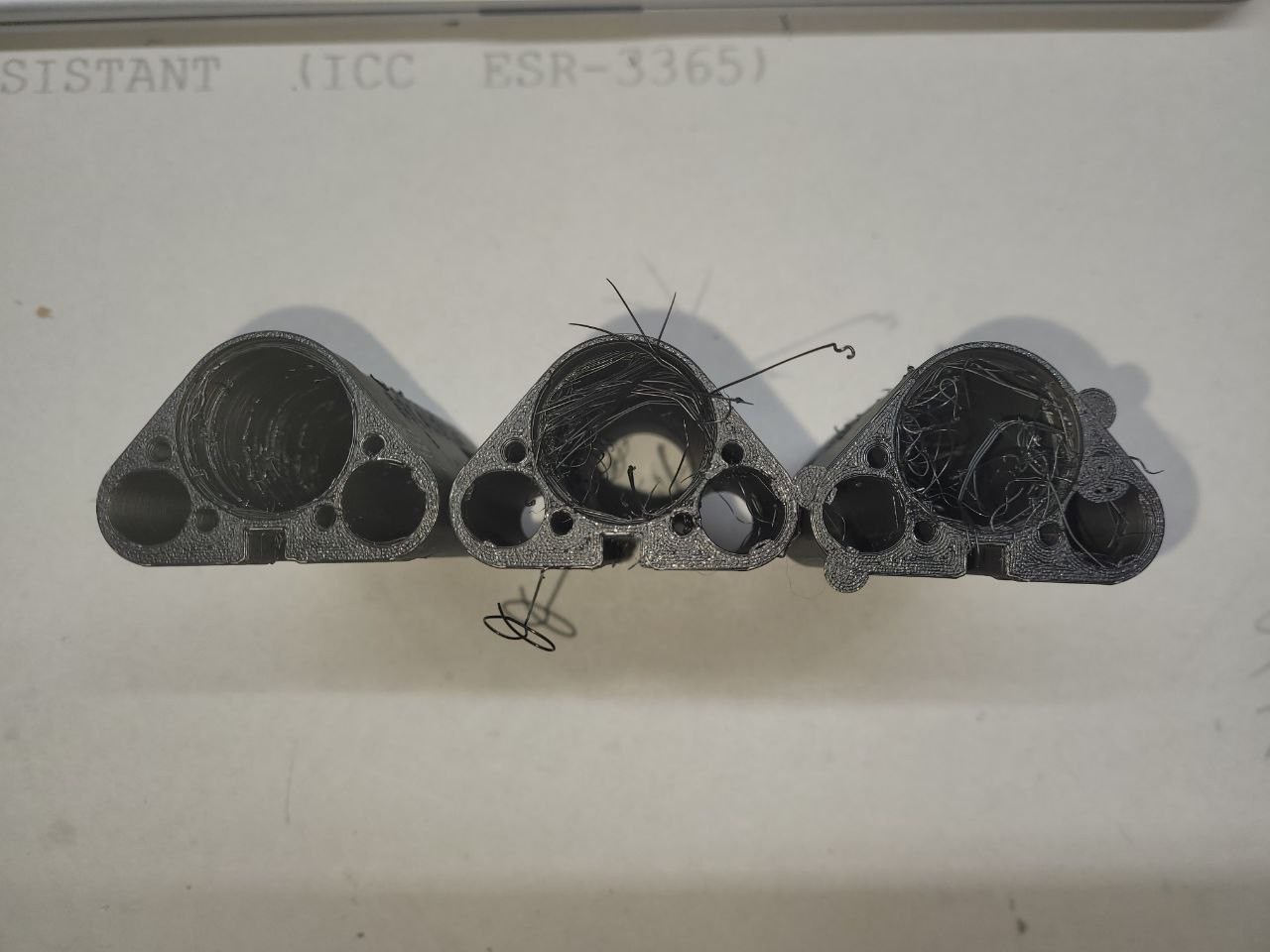

on this photo is my most recent prints. i printed the smaller parts to use less filament

left. most recent. 80% infill. normal manually painted supports.

center. second test print. 85% infill. auto generated normal supports.

right. my first test print. 95% infill. auto generated tree supports.

i added brims to all three of these prints just in case to prevent any edges pulling off the bed. i figured what the hell i was trying what ever i could.